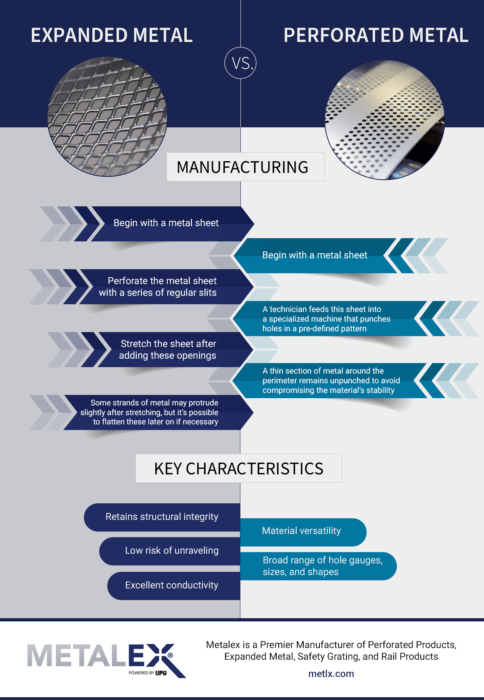

Expanded Metal vs. Perforated Metal

Comments Off on Expanded Metal vs. Perforated MetalBoth expanded metal and perforated metal are suitable for use in ventilation or drainage applications.

Additionally, their integration of geometric patterns, makes both a popular aesthetic element added to various fixtures and structures.

Despite their similarities in function, these two metals are distinct; they require the use of different manufacturing methods, exhibit different characteristics, and have different best use cases. Understanding the differences between them is critical when selecting one or the other for an application.

In the following blog post, we provide an overview of how perforated and expanded metal differ, outlining how they’re manufactured, key characteristics, and ideal applications.

All About Expanded Metal

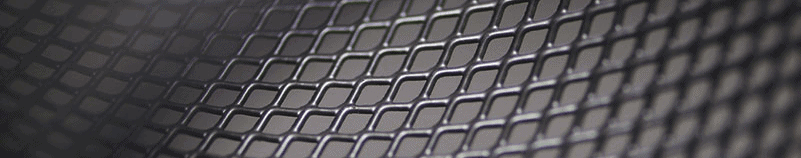

For ventilation and drainage products, expanded metal is a strong and cost-effective option.

For ventilation and drainage products, expanded metal is a strong and cost-effective option.Manufacturing Method for Expanded Metal

The key to expanded metal’s strength is in its manufacturing process. The first step is to perforate the sheet with a series of regular slits. Stretching the sheet after adding these openings creates the distinctive, repeating diamond pattern that distinguishes expanded metal from other material options. After the stretching process, some strands of metal may protrude slightly, but it’s possible to flatten these later on if necessary or desired.

There are two key advantages to this technique:

- It decreases the amount of material waste produced—therefore increasing material utilization—which translates to lower production costs.

- It creates materials with greater structural strength than that of materials with holes punched directly into them (i.e., perforated metal).

Key Characteristics of Expanded Metal

As indicated above, expanded metal retains its structural integrity better than perforated metal. In addition to this property, other key characteristics include low risk of unraveling (compared to woven mesh) and excellent conductivity.

Ideal Applications for Expanded Metal

When choosing to use expanded metal for an application, some of the key considerations include thickness and strand dimension, both of which depend on the structure’s requirements. It is available in a wide range of materials, mesh sizes (including near-transparent thickness), and pattern designs to suit different use cases.

Some of the most common applications for which expanded metal is ideal include:

- Airbags

- Animal Flooring

- Architectural components

- Automotive racks

- Car grilles

- Automotive racks

- Ceiling panels

- Chimney caps

- Ceiling panels

- Lockers

- Machine guards

- Screening

- Screening

- Speaker grilles

- Trailer flooring

- Vents

- Waste receptacles

All About Perforated Metal

Perforated metal is the preferred choice for use in certain applications such as filtration equipment.

Manufacturing Method for Perforated Metal

Like expanded metal, perforated metal begins as a steel sheet. However, rather than slicing and stretching the sheet, a technician feeds the base material into a specialized machine that punches holes in a pre-defined pattern (typically either straight or staggered lines of holes). The machine usually leaves a thin section of metal around the perimeter unpunched to avoid compromising the material’s stability.

The perforation process does, by necessity, generate waste. While the excess metal can be recycled, doing so may increase the overall project cost. Manufacturing sheets with larger holes produces more material waste—resulting in higher production costs—so customers with such requirements should consider if expanded metal is a better fit for their budget.

Key Characteristics of Perforated Metal

Compared to expanded metal, perforated metal’s main advantage is its versatility. It is available in a broad selection of variations, with different material, hole gauge, hole size, and hole shape options.

Ideal Applications for Perforated Metal

As perforated metal is available in many different variants, it lends itself to use in a wide range of applications. Some examples include the following, although perforated metal applications are by no means limited to this list:

- Acoustical enclosures

- Architectural structures

- Electronic enclosures

- Farm equipment

- Filtration

- Grain dryers

- Home appliances

- HVAC equipment

- Lighting fixtures

- Pharmaceutical systems

- Speaker grilles

- Store displays and fixtures

Expanded and Perforated Metal Solutions From Metalex

At Metalex, we recognize the value of both expanded metal and perforated metal. As such, we maintain a broad selection of perforated metal materials and expanded metal products for our customers. Whichever material you need, our expert sales and engineering team will ensure you get the right product for your application and requirements.

For additional information about our offerings or assistance choosing one for your next project, contact us or request a quote today.

Expertise and Information in the Metalex Resource Library

Comments Off on Expertise and Information in the Metalex Resource Library Metalex is proud to present our Resource Library. Since our founding in 1962, we have provided metal stamping solutions to clients across such diverse industries as automotive, railroad, and architecture, among many others.

Metalex is proud to present our Resource Library. Since our founding in 1962, we have provided metal stamping solutions to clients across such diverse industries as automotive, railroad, and architecture, among many others.As a result, we have been involved in almost every aspect of the manufacturing and mechanical assembly process for decades. Our experience and expertise allows us to offer our clients assistance with a range of processes and challenges to meet project specifications in a timely and cost-effective manner.

The Metalex Resource Library brings together our decades of experience and draws on our first-hand industry knowledge and presents it in a large collection of guides and documents. They are meant to help our clients choose the correct products for their projects, properly install and operate them, and to help get the longest life out of their equipment.

Metalex and Morton Brochures

Available in our Resource Library are a number of our brochures such as the Metalex Company Brochure and the Morton Industrial Brochure. In the Metalex brochure, you see what we offer that sets us apart and ahead of the curve.

The Metalex brochure has clear technical information and specification that provide a quick glimpse into our full line of products such as:

- Light meshes

- Large and heavy meshes

- Perforated products

The brochure also includes general technical data to help you make the most informed decision when purchasing.

Metalex recently combined operations with Morton Manufacturing Company, founded in 1903, and we are proud to also offer a full line of safety grating options, including:

- Open-Grip® Safety Grating

- Tread-Grip® Safety Grating

- Deck Span® Safety Grating

A Collection of Useful Guides

The Metalex Resource Library also has a variety of other helpful guides like the Morton Rail Products Running Board Worksheets¸ the Morton Running Board Brochure, and the Morton Industrial Flyer. These are all designed to help you inspect, compare, and install our products to allow safety, maneuverability, and efficiency throughout your facilities.

We also offer a useful How to Specify Safety Grating guide with everything you need to know about our Open-Grip®, Deck-Span®, and Tread-Grip® Safety Grating and Stair Treads before installation in your facility, plant, or place of business for additional safety. The guide clearly details a number of important factors such as:

- Intended Use

- Areas for proper use of Open-Grip®, Deck-Span®, and Tread-Grip® Safety Grating and Stair Treads

- Storage and Handling

- Proper handling techniques for efficient installation

- Grating Materials

- Technical specifications including material, material thickness, and selection width and length

- Recommended Installation Techniques and Conditions

Our dedication to customer service—our ISO 9001:2008 registration is also available for free download—means that we will work with you to help you achieve the results you are looking for.

Visit our Resource Library today, and if you have any questions, please feel free to contact a representative to find out how we can help you meet all your project requirements.

For ventilation and drainage products,

For ventilation and drainage products,